What is PP Film? Applications of Filler Masterbatch in PP Film Production

Polypropylene (PP) film is one of the most widely used plastic films in packaging, labeling, and industrial sectors. Known for its excellent mechanical properties, chemical resistance, and clarity, PP film has become an essential material in modern manufacturing. Its versatility allows it to serve various purposes, from flexible packaging for food and pharmaceuticals to industrial applications such as laminates, protective films, and stationery products.

PP film is valued for its lightweight structure, ease of processing, and ability to withstand high temperatures. These characteristics make it a preferred choice for many manufacturers looking for reliable, durable, and cost-effective plastic film solutions.

1. Understanding PP Film

PP film is produced through a process called extrusion, where polypropylene resin is melted and stretched into thin layers. Depending on the intended use, PP film can be manufactured as cast film (CPP) or biaxially oriented film (BOPP).

- Cast Polypropylene Film (CPP): Produced by extruding molten polymer onto a chilled roller, resulting in a film with high clarity, smooth surface, and excellent flexibility. CPP film is ideal for applications that require transparency, high-quality printing, and good sealability. Common uses include food packaging, laminated structures, and medical packaging.

- Biaxially Oriented Polypropylene Film (BOPP): Undergoes stretching in both the machine direction and transverse direction, providing superior strength, barrier properties, and optical qualities. BOPP film is widely used for snack food packaging, labels, decorative films, and laminates. Its excellent tensile strength and clarity make it a favorite choice for high-performance packaging.

PP film is appreciated for its moisture resistance, chemical stability, low weight, and recyclability. It also offers good sealing properties, making it suitable for packaging that requires airtight protection. Manufacturers can adjust film thickness, transparency, and surface characteristics to meet specific industry requirements, giving PP film a high degree of versatility.

2. The Role of Filler Masterbatch in PP Film Production

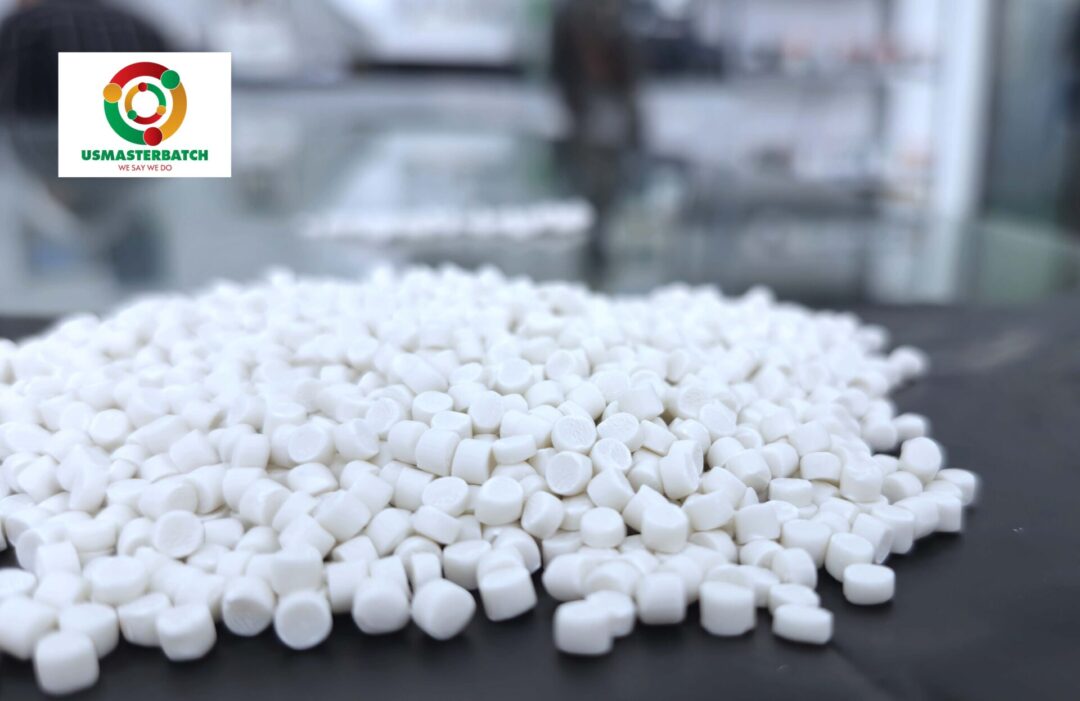

One of the key factors that influence the performance, cost-effectiveness, and functional properties of PP film is the use of filler masterbatch. Filler masterbatch is a concentrated mixture of additives, including inorganic materials like calcium carbonate (CaCO₃), talc, or silica, evenly dispersed in a polymer carrier. By incorporating filler masterbatch into polypropylene, manufacturers can achieve several benefits.

2.1. Improved Mechanical Properties

Filler masterbatch enhances the mechanical strength, stiffness, and dimensional stability of PP film. Calcium carbonate, for example, increases rigidity, making the film more resistant to tearing, puncturing, or stretching. This allows manufacturers to produce thinner films without sacrificing performance, reducing material consumption and production costs.

2.2. Enhanced Processing Efficiency

Filler masterbatches optimize melt flow during extrusion and reduce shrinkage. This results in films with consistent thickness, better surface quality, and fewer defects. Enhanced processing performance also allows higher production speeds and less material wastage, which is particularly important for large-scale industrial manufacturing.

2.3. Cost Reduction

Inorganic fillers such as CaCO₃ are significantly less expensive than polypropylene resin. By partially replacing PP with fillers, manufacturers can reduce raw material costs while maintaining the desired mechanical and optical properties. This cost advantage makes filler masterbatch an attractive solution for price-sensitive markets without compromising product quality.

2.4. Custom Functional Properties

Filler masterbatches allow for the customization of PP film properties according to specific application requirements. They can improve opacity, whiteness, thermal stability, and even add anti-blocking, anti-slip, or anti-static characteristics. This flexibility ensures that PP films can meet the needs of diverse industries, from food packaging to electronics.

2.5. Environmental and Sustainability Benefits

Sustainability is increasingly important in the plastics industry. Filler masterbatches reduce the amount of pure polymer used, lowering the overall carbon footprint of PP film production. Many fillers are derived from natural minerals, providing an eco-friendly alternative to fully synthetic polymers and helping manufacturers meet environmental regulations and sustainability goals.

Conclusion

PP film is a versatile, high-performance material that plays a critical role in packaging, labeling, and industrial applications. Its mechanical strength, chemical resistance, and clarity make it suitable for a wide range of uses. The integration of filler masterbatch in PP film production offers multiple advantages, including improved mechanical properties, enhanced processing efficiency, cost reduction, customizable functionality, and environmental benefits.

As demand for high-quality, cost-effective, and sustainable PP films continues to grow, filler masterbatches remain an essential tool for manufacturers. By carefully selecting the appropriate filler and optimizing its concentration, manufacturers can produce films that meet specific industry requirements while maximizing efficiency and minimizing costs. Ultimately, filler masterbatches contribute to producing PP films that are not only strong and versatile but also economically and environmentally sustainable, ensuring their continued relevance in modern manufacturing.

什么是PP薄膜?填料母粒在PP薄膜生产中的应用

聚丙烯(PP)薄膜是包装、标签和工业领域中最广泛使用的塑料薄膜之一。由于其优异的机械性能、耐化学性和透明度,PP薄膜已成为现代制造业的重要材料。它用途广泛,从食品和药品的柔性包装,到工业应用如复合膜和保护膜,都能胜任。

PP薄膜因轻便、易加工、耐高温而受到重视。这些特性使其成为制造商寻求可靠、耐用且经济高效塑料膜解决方案的首选。

1. PP薄膜

PP薄膜通过挤出工艺生产,即将聚丙烯树脂熔融并拉伸成薄层。根据用途不同,PP薄膜可以生产为流延膜(CPP)或双向拉伸薄膜(BOPP)。

- 流延PP薄膜(CPP): 将熔融聚合物挤出到冷却辊上,形成透明度高、表面光滑、柔韧性好的薄膜。CPP薄膜适用于需要高透明度、高印刷质量和良好封口性的应用,如食品包装、复合膜和医药包装。

- 双向拉伸PP薄膜(BOPP): 在机器方向和横向同时拉伸,具有优异的强度、阻隔性能和光学特性。BOPP广泛用于零食包装、标签、装饰膜和复合膜。其高拉伸强度和透明度使其成为高性能包装的理想选择。

PP薄膜因其防潮、化学稳定、轻量和可回收的特性而受到青睐。同时,它还具有良好的封口性能,非常适合需要气密保护的包装。制造商可以根据行业需求调整薄膜厚度、透明度和表面特性,使PP薄膜具有高度的适应性。

2. 填料母粒在PP薄膜生产中的作用

影响PP薄膜性能、成本和功能性的重要因素之一是使用填料母粒。填料母粒是一种浓缩添加剂混合物,包括碳酸钙(CaCO₃)、滑石粉或二氧化硅等无机材料,均匀分散在聚合物载体中。将填料母粒加入聚丙烯可带来多重优势。

2.1. 提高机械性能

填料母粒可增强PP薄膜的机械强度、刚性和尺寸稳定性。例如,碳酸钙可增加薄膜刚性,使薄膜更耐撕裂、穿刺或拉伸。这允许制造商生产更薄的薄膜而不影响性能,从而减少材料消耗和生产成本。

2.2. 提升加工效率

填料母粒可优化挤出时的熔体流动性并减少收缩,确保薄膜厚度均匀、表面质量良好并降低缺陷率。加工效率的提升还可增加产量并减少材料浪费,对于大规模生产尤为重要。

2.3. 降低成本

无机填料如碳酸钙通常比聚丙烯树脂便宜。通过部分替代聚丙烯,制造商可以在保持所需机械和光学性能的同时降低原材料成本,使填料母粒成为价格敏感市场的理想方案。

2.4. 定制功能性

填料母粒可根据应用需求定制PP薄膜特性,如提高不透明度、亮度、热稳定性,甚至赋予抗粘连、抗滑移或抗静电性能。这种灵活性确保PP薄膜能够满足从食品包装到电子产品的不同工业需求。

2.5. 环境和可持续性优势

在塑料行业,可持续性越来越重要。使用填料母粒可减少纯聚合物用量,从而降低PP薄膜生产的整体碳足迹。许多填料来自天然矿物,为可持续生产提供环保替代方案,帮助制造商满足环保法规和可持续发展目标。

总结

PP薄膜是一种多功能、高性能材料,在包装、标签和工业应用中发挥着关键作用。其机械强度、化学稳定性和透明度使其适用于各种用途。在PP薄膜生产中使用填料母粒可带来多重优势,包括提高机械性能、提升加工效率、降低成本、实现功能性定制及环境友好。

随着对高质量、经济高效和可持续PP薄膜的需求不断增长,填料母粒在现代制造中扮演着越来越重要的角色。通过合理选择填料种类和浓度,制造商可以生产符合行业要求的薄膜,同时实现高效生产和成本优化。最终,填料母粒帮助制造商生产出强韧、多功能且环保的PP薄膜,确保其在现代制造业中的持续应用价值。